New partnership to help Britishvolt stay carbon net zero

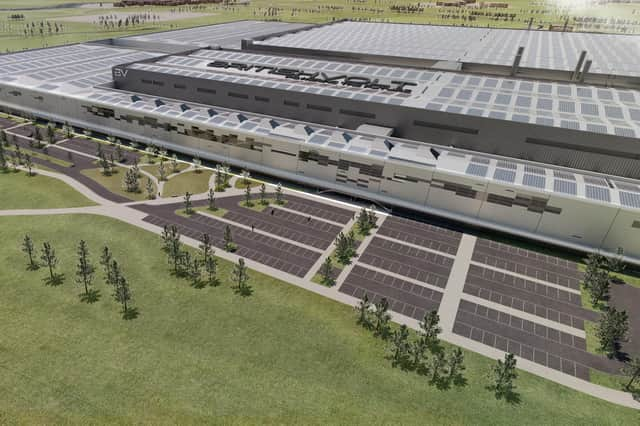

Britishvolt has entered into a strategic partnership with Circulor to set a new benchmark in CO2 footprint tracking across all of its process, including the build of its gigaplant in Cambois and wider supply chain monitoring.

The news is the latest major milestone for Britishvolt’s quest to assist vehicle OEMs on their roadmap to electrification.

Advertisement

Hide AdAdvertisement

Hide AdBritishvolt has instructed Circulor to trace building material supply chains to fully understand inherited CO2 emissions used in the gigaplant and in the process make this information readily available.

Circulor will provide Britishvolt with a dynamic and living digital building inventory for the gigaplant during the build phase to set a new global benchmark for sustainable/green construction and manufacturing, helping their quest to build some of the world’s most low carbon battery cells.

Orral Nadjari, Britishvolt CEO/founder, said: “This is another prime example of Britishvolt going above and beyond on its mission to decarbonise society.

"This data will allow for a complete and honest audit of the company’s net zero ambitions.

Advertisement

Hide AdAdvertisement

Hide Ad"We will set a new CO2 footprint traceability tool that will redefine industry standards.

"Producing some of the greenest batteries on the planet isn’t just about tracking the raw materials supply chain, it’s also about making sure the facilities we build, the energy we are supplied, in fact everything we do, is as sustainable and ethically delivered as possible.

“We are very excited to be partnering with Circulor on this project.

"This project is the right thing for UK plc, and its people, on the roadmap to a low carbon, sustainable future.”

Advertisement

Hide AdAdvertisement

Hide AdLuise Müller-Hofstede, Client Partner at Circulor, said: “We are truly excited to be working with Britishvolt and to have found this strong partner for jointly setting and, more importantly, demonstrating a new global standard for green construction and battery cell production.

“We believe this is pioneering work, tracking both CO2 emissions from construction materials for a large building, and its social, economic and environmental impact on its local and regional economy, for the first time.

"Doing the right thing is contagious and being part of Britishvolt’s journey is truly exciting.

"With Britishvolt racing forward, I hope this will encourage the wider industry to act responsibly. We all have to work together, collectively, on the road map to net-zero.”

Advertisement

Hide AdAdvertisement

Hide AdThe development is a major boost for Northumberland, and indeed the country, and will bring around 3,000 direct highly-skilled jobs and another 5,000 more in the associated supply chains.

Enabling works started on the site Septepmber 6, following a unanimous planning application approval in July.

Britishvolt is on target to manufacture some of the world’s most sustainable, low carbon battery cells on the site of the former Blyth Power Station coal stocking yard located in Cambois.

The project will be built in phases towards total capacity by end-2027 onwards. First production will start at the end of 2023.

Advertisement

Hide AdAdvertisement

Hide AdOnce at full capacity, the Gigaplant will have a production capability equating to approximately enough cells for around 300,000 electric vehicle battery packs per year, intended primarily for the automotive industry.

It will be the first large full cycle gigaplant in the UK.